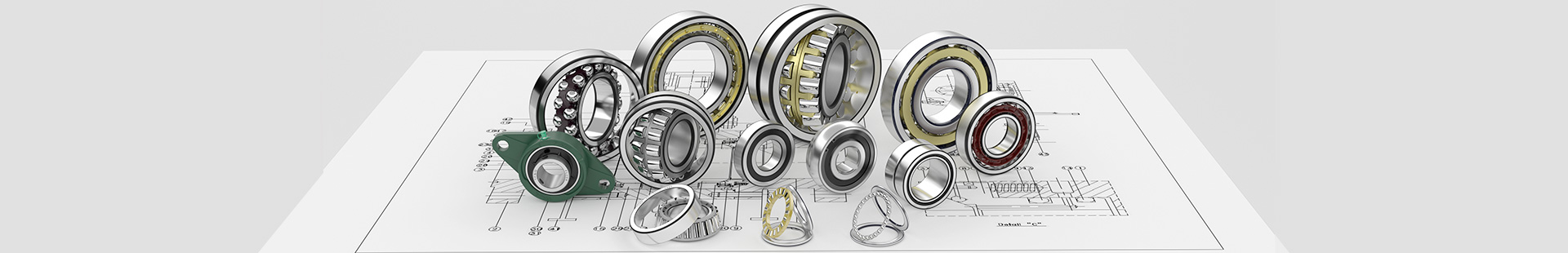

How to identify the pros and cons of bearings by appearance?

We all know that when a car can be reached, the engine is indispensable first, and the other important thing is the wheels. One of the most important components of a wheel that can rotate is the bearing. The quality of the bearing directly affects the operation of the tire, and the inspection of all bearings is particularly important.

The following items should be paid attention to in the visual inspection:

(1) Various cracks, such as raw material cracks, forging cracks, heat treatment cracks and grinding cracks. These cracks will become the source of stress concentration and expand rapidly during the operation of the bearing, causing the bearing to rupture, which will affect the life and work of the bearing. Security has a big impact.

(2) Various mechanical scars, such as abrasion, scratches, crushing, bruises, etc., will cause poor bearing installation, cause eccentric load and stress concentration, and reduce rotation accuracy and service life.

(3) Rust, black skin and pitting. The latter two are defects that easily store moisture and dirt, and are easy to develop into rust. Corrosion is a source of pollution that causes poor installation, early wear and fatigue. Severe corrosion will cause the bearing to be scrapped.

(4) Peeling and folding. The parts of these two defects are not firmly bonded to the base metal, and there are often decarburization or carbon-poor phenomena around them to varying degrees. The materials are easy to collapse, dent or wear, which affects the life and accuracy of the bearing. Very unfavorable.

(5) The riveting or welding quality of the cage is mainly to observe whether the rivet head is offset, skewed, loose, lacking meat or "double eyelids", whether the welding position is correct, whether the welding point is too large or too small, and whether the welding is not strong Or excessive welding can cause jamming of rolling elements.

Whether the quality of the pressure slope, edge closing, caulking and gouging of certain cages is guaranteed, whether the rolling elements can not fall out of the cage and can rotate freely. If these points do not meet the requirements, the small ones will cause the bearing noise and rotation accuracy to decrease , The cage may fall apart, causing mechanical failure or accident.