Tapered roller bearings

Time: 2021-Mar-Sat

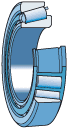

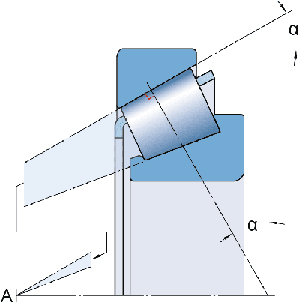

Tapered roller bearings are designed to accommodate combined loads, that is, radial and axial loads acting simultaneously. The extension line of the raceway intersects at the same point on the bearing axis, to achieve true rolling, so it has a low friction torque during operation. The axial load capacity of tapered roller bearings increases as the contact angle α increases. The size of the contact angle (usually 10° to 30°) is related to the calculation coefficient e (according to the data sheet): the greater the value of e, the greater the contact angle.

Low friction

long lasting

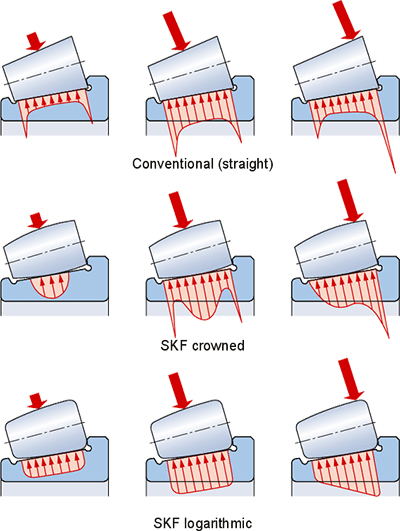

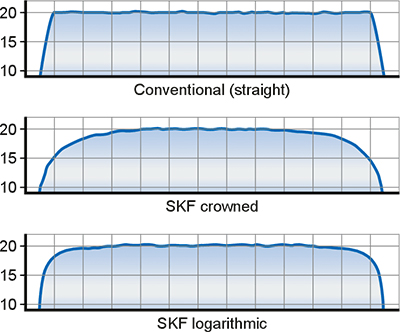

The optimized surface treatment of the contact surface between the roller and the raceway is conducive to the formation of a hydrodynamic lubricant film.

Consistency of roller profile and size

The manufacturing tolerances and dimensional accuracy of the rollers integrated in SKF tapered roller bearings are so precise that they are almost identical. This provides the best load distribution to reduce noise and vibration levels, and enables more precise preloading.

Rigid bearing applications

A single-row tapered roller bearing usually needs to be adjusted together with another tapered roller bearing. By applying preload, rigid bearing applications can be realized.

Running-in phase with a drop in peak temperature

Tapered roller bearings usually have a running-in period, during which the conventionally designed tapered roller bearings experience a lot of friction, leading to wear. This effect will cause the bearing temperature to rise . Under the premise of accurate bearing installation and lubrication, the use of tapered roller bearings can greatly reduce friction, wear and frictional heat.

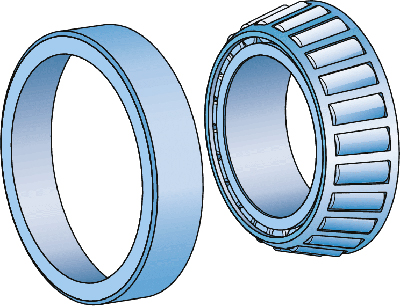

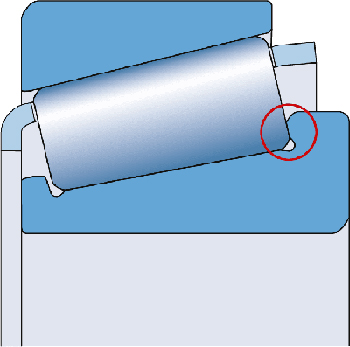

That is, the inner ring (inner ring assembly) with roller and cage assembly can be installed separately from the outer ring. In addition, the detachable parts are interchangeable. This facilitates installation, removal and maintenance inspection procedures.